Call: 07313726381

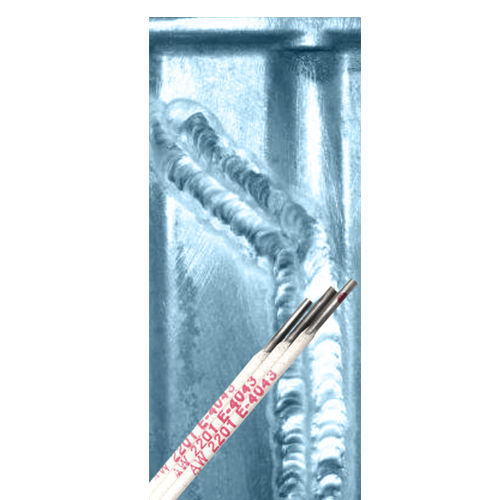

E 309L -16

Price 200.0 INR/ Piece

MOQ : 100 Pieces

E 309L -16 Specification

- Usage

- WELDING

- Material

- STAINLESS STEEL

- Color

- GREY

E 309L -16 Trade Information

- Minimum Order Quantity

- 100 Pieces

- Delivery Time

- 3 Days

- Packaging Details

- BOX

- Main Domestic Market

- All India

About E 309L -16

AWS-classified, ultra-low carbon stainless steel welding electrode (23% Cr, 12% Ni) with a titania-type flux (the "-16" part), designed for joining similar stainless steels or dissimilar metals like stainless to carbon/low alloy steel, offering excellent corrosion resistance, crack resistance, and suitability for AC/DC all-position welding, ideal for petrochemical and synthetic fiber equipment.

Key Characteristics & Features:

- Composition: Deposits an extra-low carbon (L) weld metal, typically 23% Chromium and 12% Nickel, with high ferrite content for crack resistance.

- Coating (-16): A rutile (titania) type coating for smooth arc, good usability, and excellent slag removal, allowing AC or DC+ operation.

- Weldability: All-position capability (flat, vertical, overhead) with excellent mechanical properties and resistance to high-temperature oxidation/scaling.

- Corrosion Resistance: The low carbon content prevents carbide precipitation, improving resistance to intergranular corrosion, especially important for dissimilar joints.

Typical Applications:

- Joining stainless steels (like AISI 309/309L) to themselves.

- Welding dissimilar metals: Stainless steel to carbon or low-alloy steels.

- Buffer layers on clad steels or for overlaying low alloy steels.

- Equipment in the petrochemical, synthetic fiber, and nuclear industries.

Usage Notes:

- Requires baking (drying) before use.

- Use DC+ or AC, lower currents, and minimize heat input to control dilution and prevent cracking, as noted by Ador Welding and D&H Secheron.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Welding Electrodes Category

E6013 WELDING ELECTRODE

Price 110.0 INR / Box

Minimum Order Quantity : 1 Box

Material : Electrode

Usage : Industrial

Opening Pattern : AC

Aluminium Welding Electrodes

Minimum Order Quantity : 100 Kilograms

Material : Steel

Usage : Welding

Opening Pattern : DC

SUPABASE X PLUS

Price 78.0 INR

Minimum Order Quantity : 300

Material : Mild Steel

Opening Pattern : Other, Standard

E 316L-16

Price 200.0 INR / Piece

Minimum Order Quantity : 100 Pieces

Material : STAINLESS STEEL

Usage : WELDING

Color : GREY

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry