Call: 07313726381

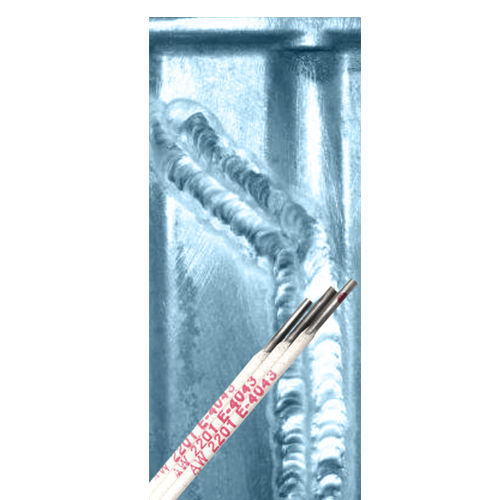

E NiCrMo4

Price 200.0 INR/ Piece

MOQ : 10 Pieces

E NiCrMo4 Specification

- Usage

- WELDING

- Material

- MILD STEEL

- Color

- GREY

E NiCrMo4 Trade Information

- Minimum Order Quantity

- 10 Pieces

- Delivery Time

- 3 Days

- Packaging Details

- BOX

About E NiCrMo4

ERNiCrMo-4 (AWS Class) is a high-performance, low-carbon, nickel-chromium-molybdenum welding filler metal (like Alloy C-276) known for exceptional corrosion resistance, especially to pitting, crevice corrosion, and stress corrosion cracking in aggressive chemical environments, used for welding similar nickel alloys, dissimilar metals (like stainless steels), and for cladding, in industries like chemical processing, oil & gas, and pollution control.

Key Characteristics & Composition

- Base Alloy: Primarily Nickel (Ni), Chromium (Cr), and Molybdenum (Mo), with added Tungsten (W).

- Corrosion Resistance: Excellent in highly corrosive media, including reducing and oxidizing conditions, due to its high Mo content.

- Mechanical Properties: Offers good strength, ductility, and weldability, with high tensile strength in the base material.

Primary Applications

- Chemical Processing: Welding pumps, valves, pipelines, and vessels in harsh chemical environments.

- Oil & Gas: Offshore equipment and downhole components.

- Pollution Control: Flue gas desulfurization (FGD) systems.

- Pulp & Paper: Bleaching equipment.

- Dissimilar Welding: Joining nickel alloys to stainless steels or other steels.

- Surfacing/Cladding: Applying a corrosion-resistant layer to steel.

Welding Methods

- Used as TIG (GTAW) wire, MIG (GMAW) wire, and sometimes SAW.

- Typically uses Argon shielding gas and DC electrode negative (DCEN) current.

In essence, ERNiCrMo-4 provides robust, long-lasting welds in demanding industrial settings where standard steels or other alloys would quickly fail due to corrosion

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Welding Electrodes Category

E6013 WELDING ELECTRODE

Price 110.0 INR / Box

Minimum Order Quantity : 1 Box

Usage : Industrial

Material : Electrode

Product Type : WELDING ELECTRODE

Aluminium Welding Electrodes

Minimum Order Quantity : 100 Kilograms

Usage : Welding

Material : Steel

Ceriated Tungsten Electrode

Price 200.0 INR / Gram

Minimum Order Quantity : 1000 Kilograms

Usage : CERIATED TUNGSTEN ELECTODE

Material : TUNGSTEN

Product Type : ELECTRODE

Color : GREY

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry