Call: 07313726381

E 2209-15

Price 200.0 INR/ Piece

MOQ : 100 Kilograms

E 2209-15 Specification

- Material

- NICKEL ALLOYS

- Usage

- WELIDNG

- Color

- GREY

E 2209-15 Trade Information

- Minimum Order Quantity

- 100 Kilograms

- Delivery Time

- 3 Days

- Packaging Details

- BOX

- Main Domestic Market

- All India

About E 2209-15

E2209-15 describes a specific type of AWS basic-coated electrode used for welding duplex stainless steels, depositing an austenitic-ferritic weld metal with high strength, excellent resistance to pitting and stress corrosion cracking, and good impact toughness at low temperatures, ideal for applications in chemical and offshore industries.

Key Characteristics:

- Type: Basic coated electrode (SMAW/Stick electrode).

- Composition: Deposits a weld metal with ~22% Chromium, ~9% Nickel, ~3% Molybdenum, and Nitrogen, creating a duplex (mixed) structure.

- Performance: Offers high tensile strength, excellent ductility, smooth arc, spatter-free welding, and easy slag removal.

- Corrosion Resistance: Very good resistance to pitting and chloride stress corrosion cracking.

- Applications: Joining duplex stainless steels like 2205 (UNS S31803/S32205), especially in demanding environments like the chemical, petrochemical, and offshore industries.

- Welding Conditions: Typically used with DCEP (Direct Current Electrode Positive) or AC, recommended for specific heat inputs to maintain phase balance.

In essence, E2209-15 provides a strong, corrosion-resistant weld for duplex stainless steels, combining high mechanical properties with superior corrosion resistance, making it a go-to choice for critical applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Welding Electrodes Category

ZEDALLOY 550

Price 200.0 INR / Kilograms

Minimum Order Quantity : 15 Kilograms

Material : ZEDALLOY

Usage : WELDING

Color : GREY

Length : 10 Millimeter (mm)

E6013 WELDING ELECTRODE

Price 110.0 INR / Box

Minimum Order Quantity : 1 Box

Material : Electrode

Usage : Industrial

Length : 450 Millimeter (mm)

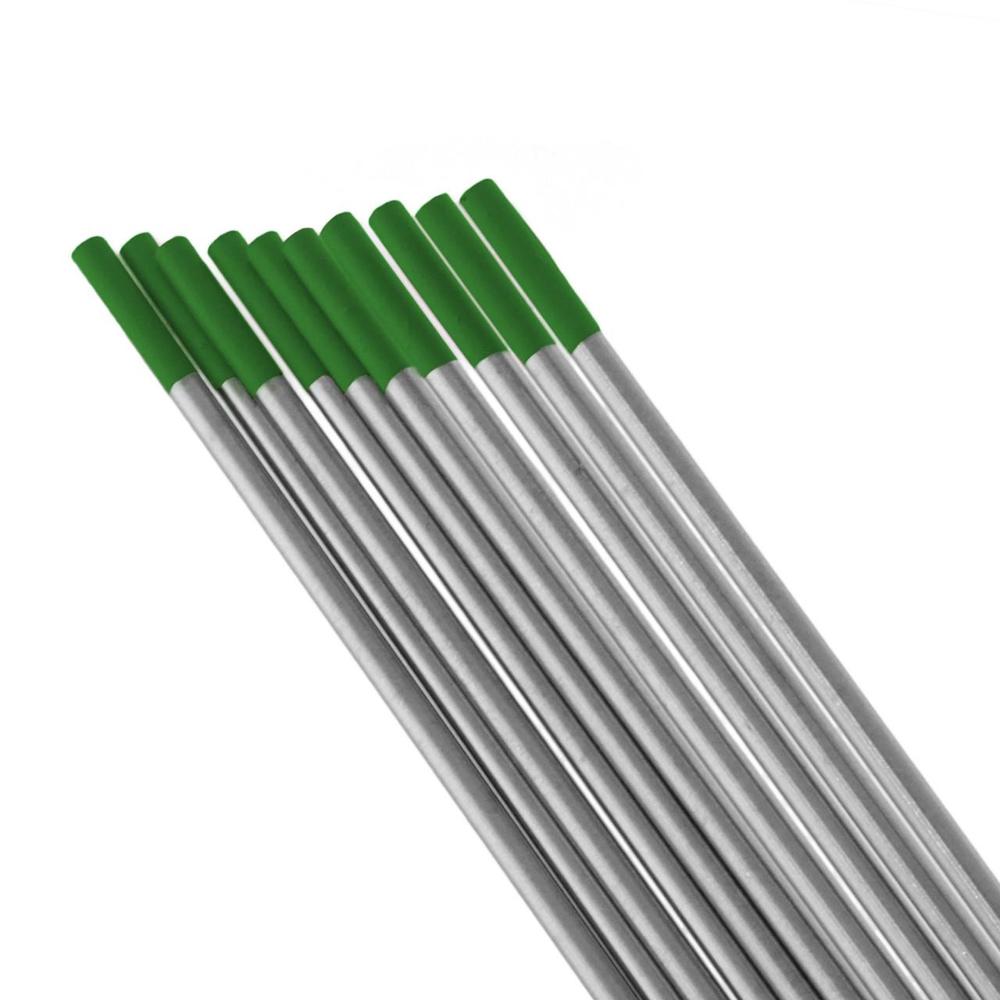

PURE TUNGSTEN

Price 200.0 INR / Kilograms

Minimum Order Quantity : 1 Piece

Material : TUNGSTEN

Usage : WELDING ELECTRODE

Color : GREY

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry