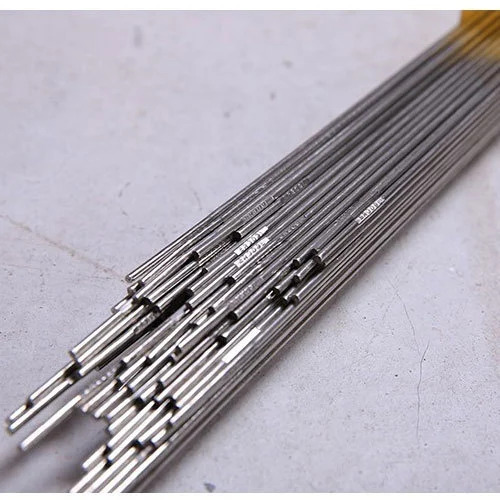

ER NiCrMo13

Price 200.0 INR/ Kilograms

ER NiCrMo13 Specification

- Application

- Welding

- Welding

- MIG, TIG

- Diameter

- 1 Centimeter (cm)

- Type

- tig / mig

- Usage

- welding

- Condition

- New

- Material

- nicalloy

- Product Type

- Welding wire

- Weight

- 1000 Grams (g)

- Color

- Silver

- Width

- 1 Millimeter (mm)

ER NiCrMo13 Trade Information

- Minimum Order Quantity

- 1 Kilograms

- Delivery Time

- 3 Days

About ER NiCrMo13

- Superior Corrosion Resistance: Excellent against strong oxidizing agents (nitric acid, chlorine), reducing acids (sulfuric, hydrochloric), and chloride-induced pitting/crevice corrosion.

- Low Impurities: Extra low carbon and silicon content prevents sensitization and intergranular corrosion, even without post-weld heat treatment.

- High Strength & Stability: Provides high mechanical strength and excellent thermal stability.

- Excellent Weldability: Minimal hot cracking sensitivity and good processing features.

- No Tungsten: Resists grain-boundary precipitation during hot forming.

- Chemical Processing: Welding Alloy 59, C-22, C-276, and joining nickel alloys to stainless steels in aggressive media.

- Marine & Offshore: Resists corrosion in seawater and chloride solutions.

- Power Generation & Pollution Control: Used in sulfuric acid coolers, digesters, and bleach plants.

- Sour Gas Environments: Approved for highest test levels in sour-gas (H2S) conditions (ISO 15156/MR0175).

- TIG/GTAW Rods, MIG/MAG Wires, Coated Electrodes (AWS A5.14/A5.14)

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Welding Wire Category

ER 4043 WELDING WIRE

Price 350.0 INR

Minimum Order Quantity : 5

Type : Welding Wire

Application : Welding of aluminum alloys, especially 6xxx series, automotive repair, general fabrication

Welding : Other, MIG (GMAW)

Condition : New

ER NiCrMo4

Price 200.0 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Type : TIG / MIG

Application : WELDING

Welding : MIG, TIG

Condition : New

ER NiCu7

Price 200.0 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Type : TIG / MIG

Application : WELDING

Welding : MIG, TIG

Condition : New

ER 70S6 MIG WIRE

Price 80.0 INR

Minimum Order Quantity : 15

Type : ER 70S6 MIG Wire

Application : Automotive, Fabrication, Construction

Welding : Other, MIG/MAG Welding

Condition : New

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry