Call: 07313726381

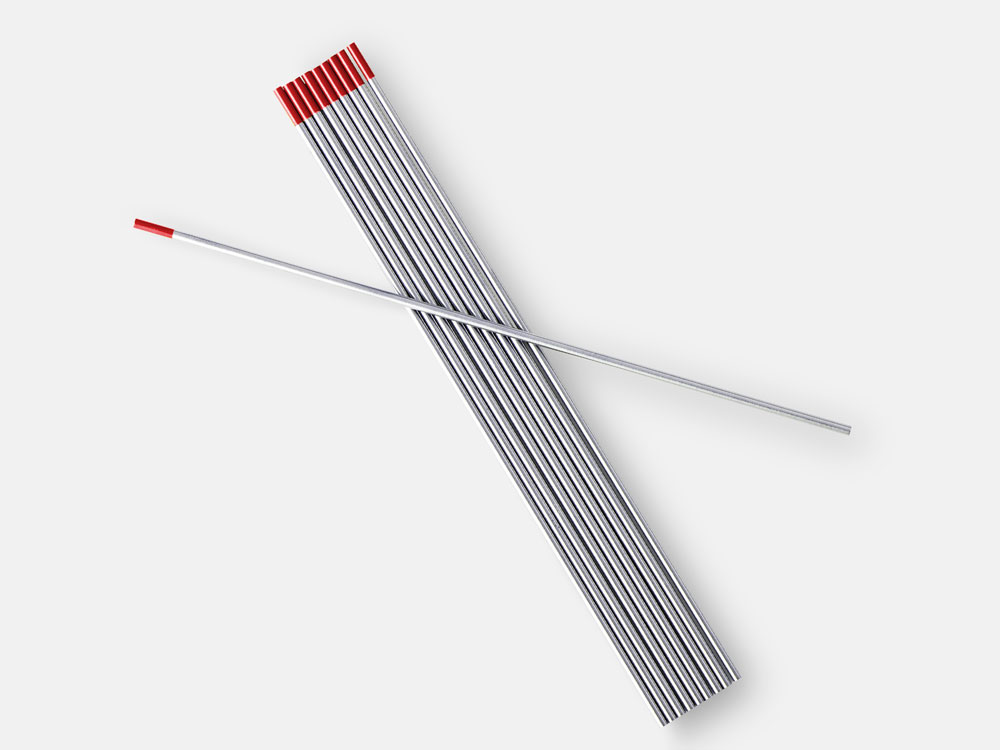

Thoriated Tungsten Electrode

Price 200.0 INR/ Gram

MOQ : 1000 Kilograms

Thoriated Tungsten Electrode Specification

- Usage

- WELDING

- Material

- TUNGSTEN

- Product Type

- TUNGSTEN ELECTRODE

- Color

- GREY

Thoriated Tungsten Electrode Trade Information

- Minimum Order Quantity

- 1000 Kilograms

- Delivery Time

- 3 Days

- Packaging Details

- ELECTRODE

- Main Domestic Market

- All India

About Thoriated Tungsten Electrode

Thoriated tungsten is a popular, durable welding electrode known for its excellent arc starting and stability, high current capacity, and low consumption rate in Direct Current (DC) applications, particularly for welding steels and nickel alloys. It is color-coded red.

Key Features

- Superior Arc Performance: Offers reliable and easy arc starting with exceptional stability during welding, which helps eliminate arc wandering.

- High Current Capacity: Has a greater current carrying capacity and performs effectively at high temperatures (up to 3,400C) compared to pure tungsten, allowing for a broader amperage range.

- Durability and Longevity: Features a low burn-off rate and maintains a sharpened point for longer periods, leading to extended electrode lifespan and less downtime for re-grinding.

- Reduced Contamination: Deposits less tungsten into the weld puddle, resulting in contamination-resistant welds.

- Composition: Typically composed of 97.3% tungsten and 1.7% to 2.2% thorium oxide, which enhances its electron emission qualities.

- Primary Application: Best suited for DC electrode negative (DCEN) or straight polarity welding on a variety of metals, including:

- Carbon and stainless steel

- Nickel alloys

- Titanium

- Copper alloys

Safety Considerations

The primary drawback of thoriated tungsten is that thorium is a mildly radioactive element. The main health risk occurs when the material is ingested or inhaled as dust during the tip grinding process.

- Always use local exhaust ventilation near the source of grinding to capture dust.

- Follow all manufacturer's warnings, instructions, and Material Safety Data Sheets (MSDS) for safe use

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Welding Electrodes Category

ZEDALLOY 350

Price 200.0 INR / Kilograms

Minimum Order Quantity : 15 Kilograms

Usage : WELDING PURPOSE

Material : SILVER

Color : SILVER

Size : 1

Nickel Welding Electrodes

Minimum Order Quantity : 100 Kilograms

Usage : Welding

Material : Nickel

Size : Different available

E NiCu 7

Price 200.0 INR / Kilograms

Minimum Order Quantity : 100 Pieces

Usage : WELDING

Material : NICKEL ALLOY

Color : GREY

E 316L-16

Price 200.0 INR / Piece

Minimum Order Quantity : 100 Pieces

Usage : WELDING

Material : STAINLESS STEEL

Color : GREY

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry