Call: 07313726381

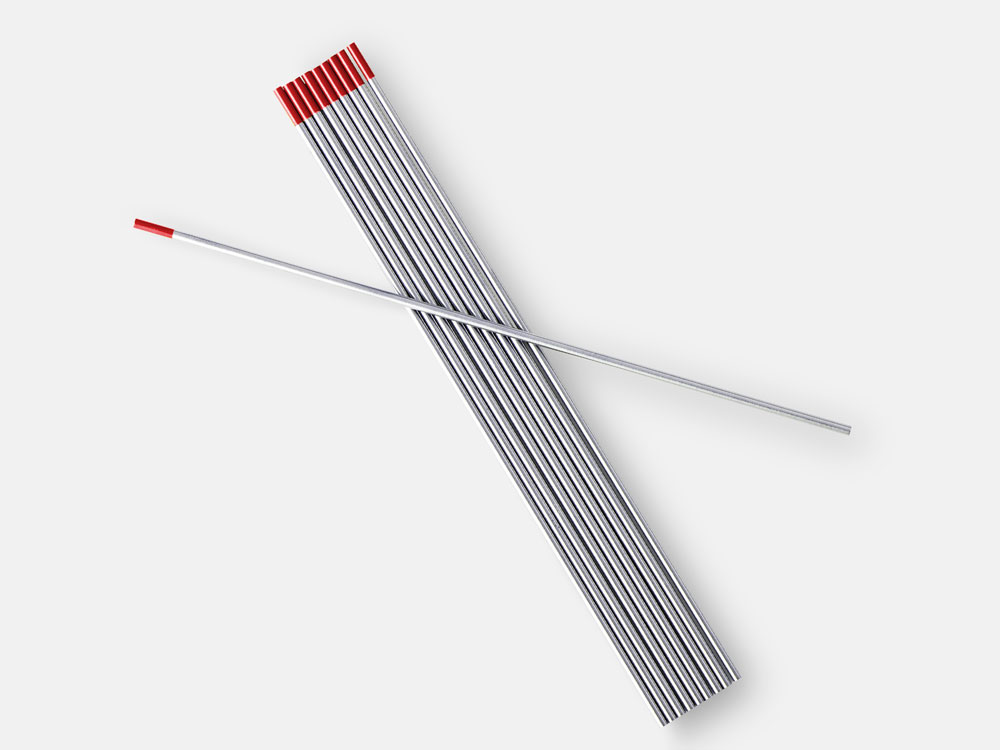

E 312-16

Price 200.0 INR/ Piece

MOQ : 100 Pieces

E 312-16 Specification

- Usage

- WELDING

- Material

- STAINLESS STEEL

- Color

- GREY

E 312-16 Trade Information

- Minimum Order Quantity

- 100 Pieces

- Delivery Time

- 3 Days

- Packaging Details

- BOX

- Main Domestic Market

- All India

About E 312-16

The E312-16 is a high-strength stainless steel welding electrode (AWS E312-16) known for its exceptional crack resistance, used primarily for joining dissimilar or difficult-to-weld steels (like high carbon, alloy, or armor steels) and for wear-resistant surfacing, featuring a duplex austenite-ferrite weld deposit with excellent mechanical properties for tough, shock-resistant applications.

Key Features

- High Strength: Produces weld metal with very high tensile and yield strength, making it great for demanding applications.

- Dissimilar Metal Joining: Excellent for bridging gaps between stainless steels, carbon steels, and other alloy steels where compatibility is difficult.

- Crack Resistance: The duplex (austenite-ferrite) structure provides superior resistance to cracking and fissuring.

- Versatile: Can be used for repair, overlay, and joining of heavy machinery parts, spring steels, and armor plating.

- All-Position: Suitable for welding in all positions (flat, horizontal, vertical, overhead).

- Rutile Type: Typically has a medium-heavy rutile coating.

Common Applications

- Welding of high-carbon, tool, die, and spring steels.

- Repair and surfacing of worn parts on earth-moving equipment.

- Joining of 13% manganese steel and other hard-to-weld steels.

- Applications requiring high mechanical strength and impact resistance, like gear teeth, forged shafts, and heavy machinery components.

Classification Breakdown (AWS)

- E: Electrode.

- 312: Indicates a specific stainless steel composition, often around 30% Chromium and 10% Nickel (30/10 type), providing excellent strength and crack resistance.

- -16: Denotes a low-hydrogen, iron powder, rutile-type coating, suitable for AC or DC+ current.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Welding Electrodes Category

Thoriated Tungsten Electrode

Price 200.0 INR / Gram

Minimum Order Quantity : 1000 Kilograms

Material : TUNGSTEN

Color : GREY

Usage : WELDING

E CuNi

Price 200.0 INR / Piece

Minimum Order Quantity : 100 Pieces

Material : NICKEL ALLOYS

Color : GREY

Usage : Welding

EBOND E6013

Price 1799 INR / Pack

Minimum Order Quantity : 200 Packs

Material : Mild Steel

Color : Silver

E 316L-16

Price 200.0 INR / Piece

Minimum Order Quantity : 100 Pieces

Material : STAINLESS STEEL

Color : GREY

Usage : WELDING

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry