Call: 07313726381

E NiCrMo 3

Price 200.0 INR/ Piece

MOQ : 100 Pieces

E NiCrMo 3 Specification

- Material

- NICKEL ALLOYS

- Usage

- welding

- Color

- GREY

E NiCrMo 3 Trade Information

- Minimum Order Quantity

- 100 Pieces

- Delivery Time

- 3 Days

- Packaging Details

- BOX

- Main Domestic Market

- All India

About E NiCrMo 3

AWS/ASME classification for a nickel-based welding electrode (like Inconel 625 filler) known for exceptional strength and corrosion resistance, used for welding nickel-chromium-molybdenum alloys, dissimilar metals (nickel to steel), and for cladding, offering performance from cryogenic to high temperatures (up to 1000F/540C) in severe environments like chemical processing, marine, and power generation. Its weld metal composition includes high levels of Nickel (Ni), Chromium (Cr), Molybdenum (Mo), and Niobium (Nb), providing superior resistance to pitting, crevice corrosion, and stress cracking in chloride-rich media.

Key Characteristics:

- Composition: High Ni, Cr, Mo, with Nb (e.g., ~60Ni, 22Cr, 9Mo, 3.5Nb+Ta).

- Performance: High strength, excellent toughness, and superior resistance to corrosion (pitting, crevice, stress corrosion cracking).

- Temperature Range: Effective from cryogenic temperatures up to around 1000F (540C).

- Weldability: Low-hydrogen coating, good operability, suitable for all-position welding, stable arc.

Common Applications:

- Joining: Inconel 625, 825, Alloy 20, and dissimilar joints between nickel alloys, stainless steels, and carbon steels.

- Surfacing/Cladding: Overlaying steel for corrosion protection in heat exchangers, marine components, and chemical equipment.

- Industries: Chemical processing, power generation, petrochemical, nuclear, and marine.

Typical Uses:

- Piping systems, reactor components, furnace parts, pressure vessels.

- Components in chloride-contaminated cooling water.

- Engine exhaust systems, aircraft ducting, line pipes.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Welding Electrodes Category

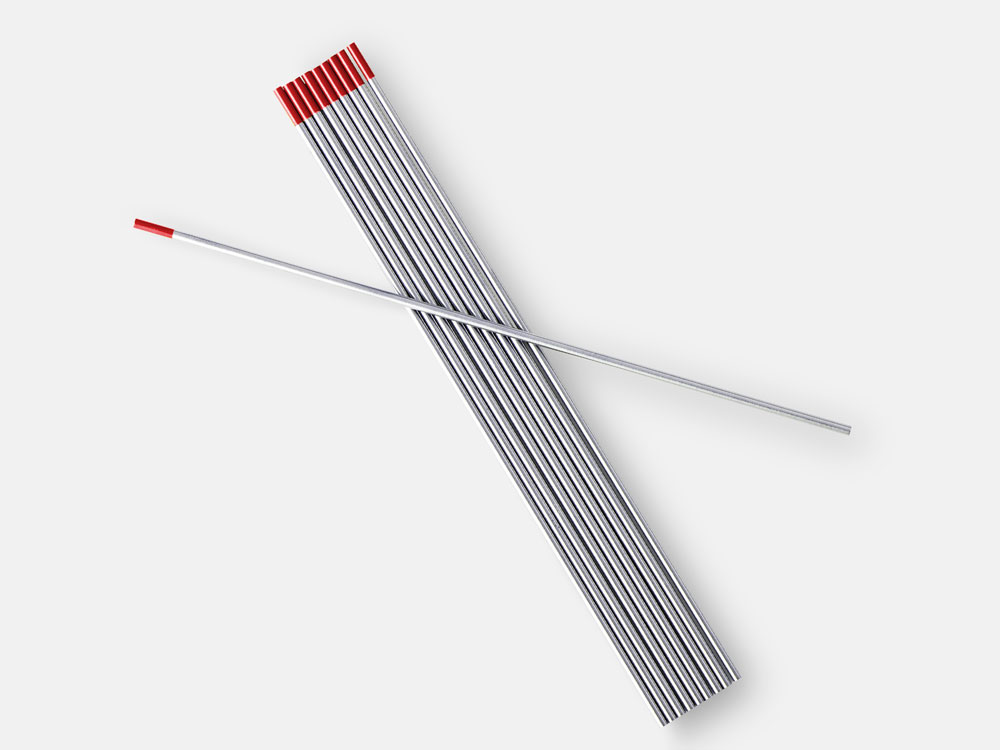

Tungsten Welding Electrodes

Minimum Order Quantity : 100 Kilograms

Usage : Welding

Material : Tungsten

Thoriated Tungsten Electrode

Price 200.0 INR / Gram

Minimum Order Quantity : 1000 Kilograms

Usage : WELDING

Material : TUNGSTEN

Color : GREY

E430-16 SS ROD

Price 200.0 INR / Piece

Minimum Order Quantity : 100 Pieces

Usage : WELDING

Material : STAINLESS STEEL

Color : GREY

E 310 -16

Price 200.0 INR / Piece

Minimum Order Quantity : 100 Pieces

Usage : WELDING

Material : STAINLESS STEEL

Color : GREY

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry