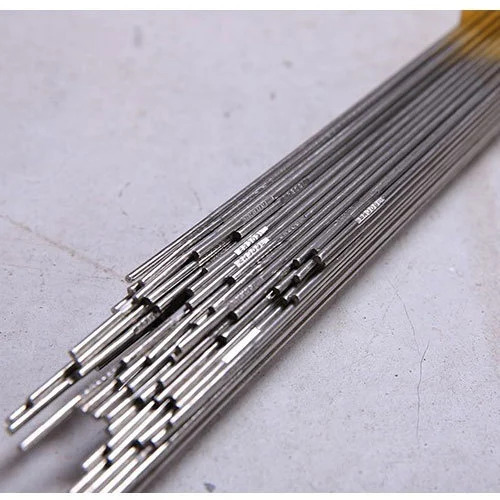

ER 1070

Price 200.0 INR/ Kilograms

MOQ : 15 Kilograms

ER 1070 Specification

- Welding

- MIG, TIG

- Application

- WELDING

- Type

- ER 1070

- Condition

- New

- Material

- ALUMINIUM

- Color

- SILVER

ER 1070 Trade Information

- Minimum Order Quantity

- 15 Kilograms

- Delivery Time

- 3 Days

- Packaging Details

- SPOOL

- Main Domestic Market

- All India

About ER 1070

ER 1070 refers primarily to a high-purity aluminum welding wire (Al99.7) known for excellent corrosion resistance, high electrical/thermal conductivity, and good ductility, used for welding 1000 series aluminum grades, busbars, and decorative items, though "ER 1070" can also describe specific steel grades or automotive hardeners, so context matters.

ER 1070 Aluminum Welding Wire (Most Common)

- Type: Commercially pure aluminum (Al99.7) filler metal.

- Properties: High electrical and thermal conductivity, excellent corrosion resistance (especially in alkaline environments), good ductility, and machinability.

- Applications: MIG/TIG welding of 1000 series aluminum (grades 1050, 1060, 1070, etc.), busbars, conductors, tanks, boats, and general fabrication.

- Characteristics: Produces welds with good color match after anodizing and requires clean base metal to avoid porosity.

Other Uses of "ER 1070"

- Steel: AISI 1070 is a medium-carbon steel (around 0.70-0.80% carbon) used in applications needing hardness and edge retention, contrasting with softer steels.

- Automotive: ER-LAC HARDENER NORMAL ER-1070 ULTRA HS is a hardener for acrylic-based automotive paints.

How to Identify

- If welding aluminum: It's the pure aluminum wire.

- If working with steel: It's a specific carbon steel grade (like AISI 1070).

- If refinishing cars: It's an automotive paint hardener.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Welding Wire Category

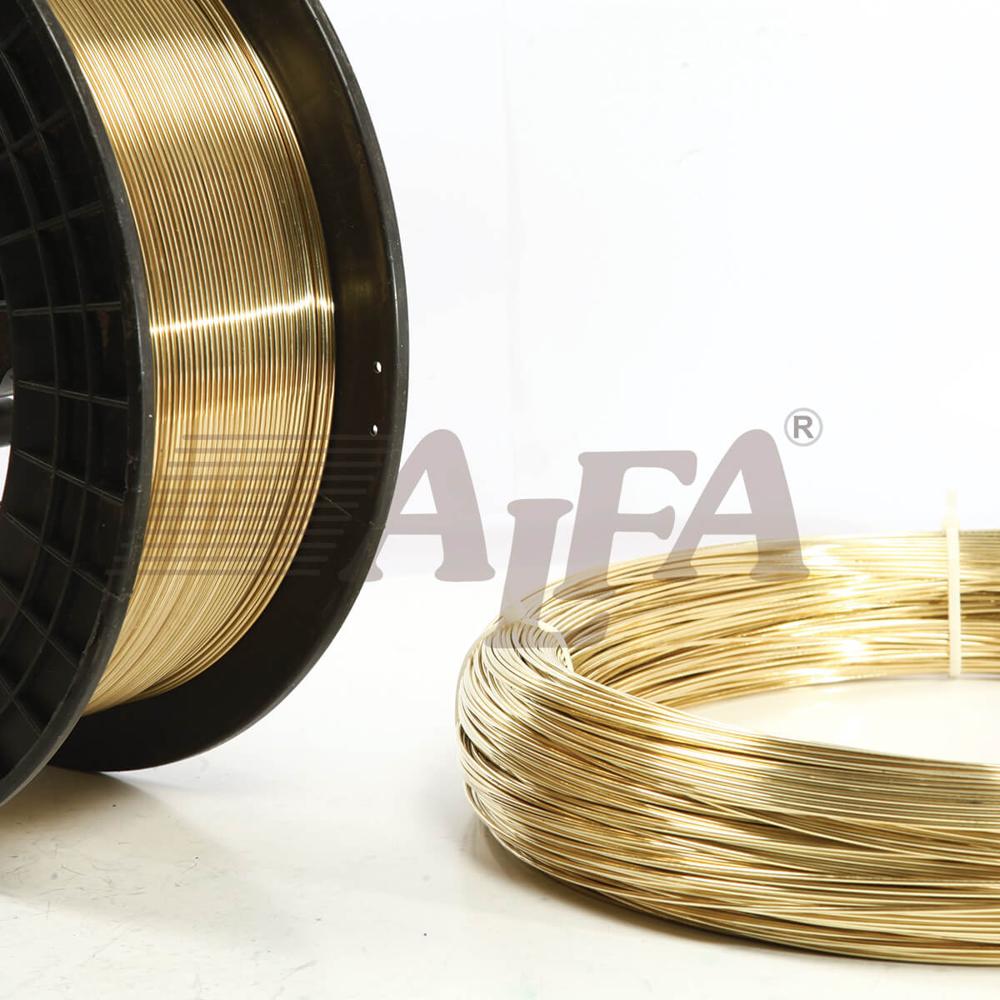

Aluminium Bronze

Price 200.0 INR / Kilograms

Minimum Order Quantity : 15 Kilograms

Condition : New

Color : GOLDEN

Type : TIG / MIG WIRE

Material : ALUMINIUM BRONZE

ER Ni-1

Price 200.0 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Condition : New

Color : silver

Type : TIG / MIG

Material : Nicalloy

ER 308H

Price 200.0 INR / Kilograms

Minimum Order Quantity : 15 Kilograms

Condition : New

Color : SILVER

Type : SS WIRE

Material : STAINLESS STEEL

ER 90SB9

Price 200.0 INR / Kilograms

Minimum Order Quantity : 15 Kilograms

Condition : New

Color : COPPER METTALIC

Type : TIG/MIG WIRE

Material : CHROME MOLLY

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry