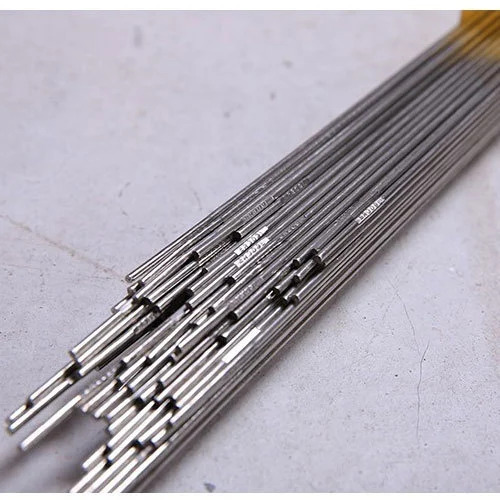

ER 304

Price 200.0 INR/ Kilograms

MOQ : 15 Kilograms

ER 304 Specification

- Welding

- MIG, TIG

- Usage

- WELDING

- Type

- SS WIRE

- Condition

- New

- Material

- STAINLESS STEEL

ER 304 Trade Information

- Minimum Order Quantity

- 15 Kilograms

- Payment Terms

- Others

- Delivery Time

- 3 Days

- Packaging Details

- Spool

- Main Domestic Market

- All India

About ER 304

ER 304 is a common designation for a stainless steel welding filler metal (wire or rod) used to join 304-type stainless steels, offering excellent corrosion resistance, good strength at high temperatures, toughness at cryogenic temperatures, and suitability for food processing and chemical equipment due to its chromium-nickel composition (around 19%Cr-10%Ni) and stable arc characteristics, making it versatile for MIG (GMAW) and TIG (GTAW) welding in various positions.

Key Characteristics

- Composition: Austenitic (non-magnetic in annealed state) stainless steel, typically 19% Chromium, 10% Nickel.

- Corrosion Resistance: Superior resistance to many chemicals, moisture, and food products, with low carbon content (especially in 304L) preventing carbide precipitation and intergranular corrosion, says www.arihantmetal.net.

- Mechanical Properties: Good strength at high temperatures, toughness at cryogenic temperatures, and excellent elongation, notes www.metalfed.com and www.arihantmetal.net.

- Weldability: Provides a stable arc, low spatter, easy slag removal, and good bead formation, allowing all-position welding for many applications, according to Made-in-China.com and tianyu.en.made-in-china.com.

Common Applications

- Welding base metals like 304, 304L, and 302 stainless steels.

- Food processing equipment, chemical tanks, and pharmaceutical manufacturing.

- Pipe welding, sheet metal work, and general industrial fabrication.

Welding Considerations

- Shielding Gas: Typically pure Argon for TIG or Argon/CO2 mixes for MIG.

- Current: DC electrode positive (DCEP) is often used.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Welding Wire Category

ER NiCrMo13

Price 200.0 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Color : Silver

Type : tig / mig

Condition : New

Welding : MIG, TIG

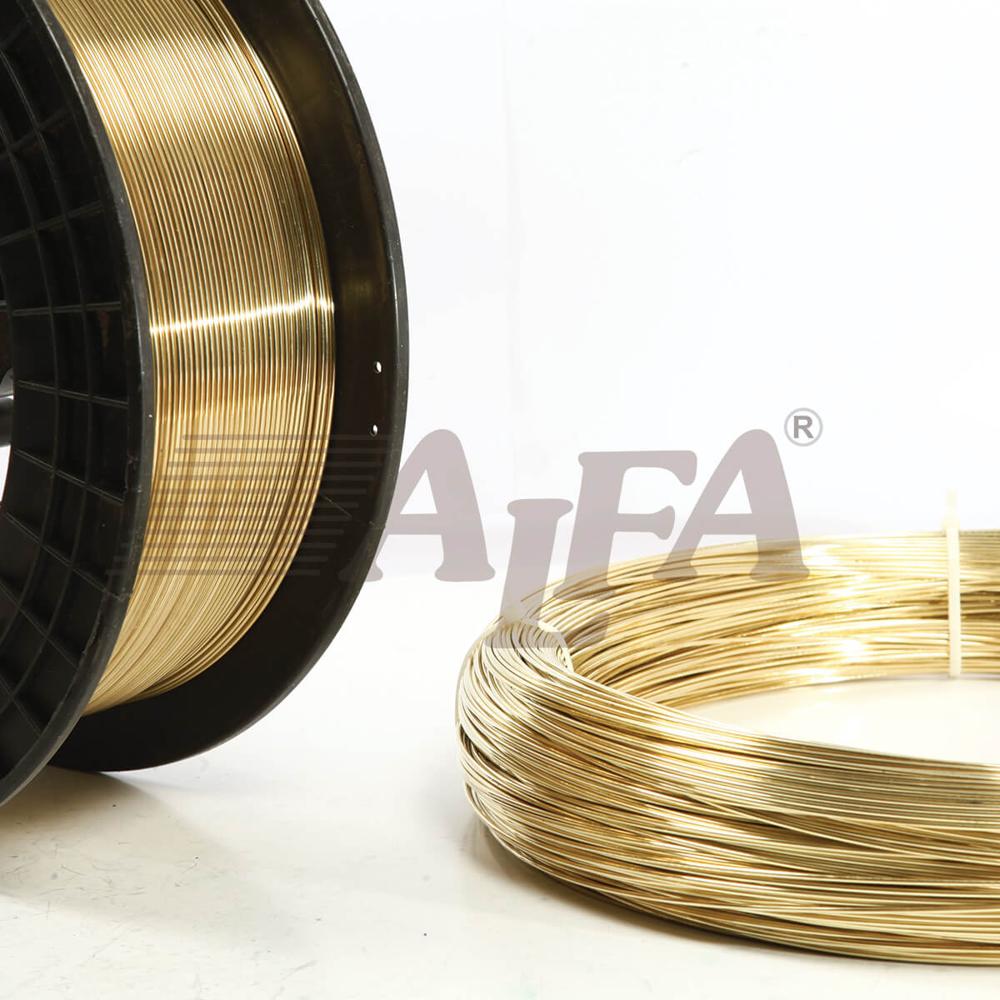

ER CuSn

Price 200.0 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Color : COPPER

Type : BRAZING WIRE

Condition : New

Welding : MIG, TIG

E71T5 FLUX CORED WIRE

Price 200.0 INR / Kilograms

Minimum Order Quantity : 15 Kilograms

Color : SILVER

Type : FLUX CORED WIRE

Condition : New

Welding : FluxCored

NICALLOY Fe3

Price 200.0 INR / Piece

Minimum Order Quantity : 10 Kilograms

Color : GREY

Type : ELECTRODE

Condition : New

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry