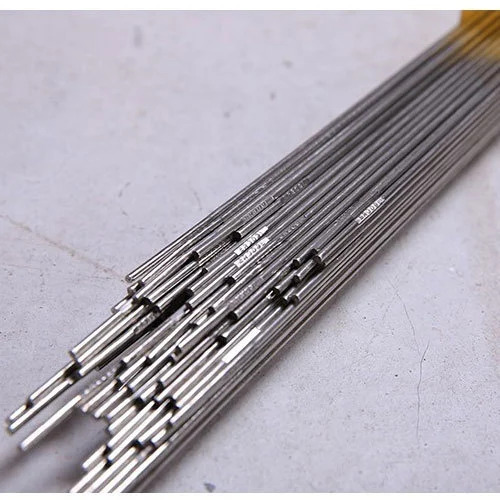

ER 316L

Price 200.0 INR/ Kilograms

MOQ : 15 Kilograms

ER 316L Specification

- Welding

- Flux-Cored

- Application

- WELDING

- Type

- SAWW WIRE

- Condition

- New

- Material

- STAINLESSS STEEL

- Color

- SILVER

ER 316L Trade Information

- Minimum Order Quantity

- 15 Kilograms

- Delivery Time

- 3 Days

- Packaging Details

- SPOOL

- Main Domestic Market

- All India

About ER 316L

ER316L is an extra-low carbon austenitic stainless steel filler metal (wire/rod) used for welding, known for excellent corrosion resistance, especially against pitting and intergranular corrosion, due to its molybdenum content and low carbon, making it ideal for chemical, petrochemical, and marine applications. It offers great weldability, good mechanical properties, and high resistance to cracking, typically containing ~18% Chromium, ~12% Nickel, and ~2-3% Molybdenum.

Key Characteristics

- Composition: Primarily 18% Chromium, 12% Nickel, and 2-3% Molybdenum (Mo).

- Low Carbon (L): Limits carbon to 0.03% max, preventing carbide precipitation (sensitization) and enhancing intergranular corrosion resistance.

- Molybdenum Content: Provides superior resistance to pitting corrosion in chloride environments and acids (sulfuric, phosphoric).

- Weldability: Offers a stable arc, good bead appearance, and excellent crack resistance due to controlled ferrite content in the weld metal.

- Corrosion Resistance: Excellent resistance to general corrosion, pitting, and crevice corrosion, even at elevated temperatures.

Common Applications

- Welding 316/316L stainless steels in equipment for chemical, petrochemical, fertilizer, and pulp/paper industries.

- Marine environments, food processing, and pharmaceutical equipment.

- Overlay applications requiring high heat and corrosion resistance.

Usage

- Used in TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) welding processes as a filler material.

- Provides radiographic quality welds with good mechanical strength and integrity

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Welding Wire Category

ER NiCrMo13

Price 200.0 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Application : Welding

Color : Silver

Material : nicalloy

Welding : MIG, TIG

ER 80SNi 2

Price 200.0 INR / Kilograms

Minimum Order Quantity : 15 Kilograms

Application : WELDING

Color : SILVER

Material : MILD STEEL

Welding : MIG, TIG

E310LT-1 FLUX CORED WIRE

Price 200.0 INR / Kilograms

Minimum Order Quantity : 15 Kilograms

Application : WELDING

Color : SILVER

Material : STAINLESS STEEL

Welding : MIG, TIG

ER 309L

Price 200.0 INR / Kilograms

Minimum Order Quantity : 15 Kilograms

Application : WELDING

Color : SILVER

Material : STAINLESS STEEL

Welding : FluxCored

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry