Call: 07313726381

E 410NiMo - 16

Price 200.0 INR/ Piece

MOQ : 100 Pieces

E 410NiMo - 16 Specification

- Usage

- WELDING

- Material

- NICKEL ALLOY

- Color

- GREY

E 410NiMo - 16 Trade Information

- Minimum Order Quantity

- 100 Pieces

- Delivery Time

- 3 Days

- Packaging Details

- BOX

- Main Domestic Market

- All India

About E 410NiMo - 16

The classification E 410NiMO -16 refers to a specific type of covered electrode (welding rod) used for manual metal arc (MMA) welding of martensitic stainless steels.

Key Characteristics

- Classification: The prefix "E" denotes an electrode for arc welding. "410NiMo" refers to the specific chemical composition (a martensitic stainless steel with Nickel and Molybdenum additions). The suffix "-16" indicates the electrode's covering type, typically a titania-based or rutile-based coating suitable for AC or DCEP (Direct Current Electrode Positive) welding, providing a stable arc and good usability in all positions except vertical down.

- Material Composition: The deposited weld metal is a soft martensitic stainless steel, typically containing:

- Chromium (Cr): 11.5 - 14%

- Nickel (Ni): 3 - 4.5%

- Molybdenum (Mo): around 0.5%

- Carbon (C): low content (<0.04%)

- Properties: The weld metal is air-hardening but is designed to offer a good balance of high strength, good toughness, and excellent resistance to corrosion, erosion, cavitation, and abrasion. The nickel and molybdenum content improves ductility and crack resistance compared to standard 410 electrodes.

- Post-Weld Heat Treatment (PWHT): Because the weld metal is air-hardening, preheating to a maximum of 150C (302F) and a post-weld heat treatment (tempering or normalizing) are generally required, especially for thicker materials or critical applications, to achieve optimal toughness and prevent cracking

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Welding Electrodes Category

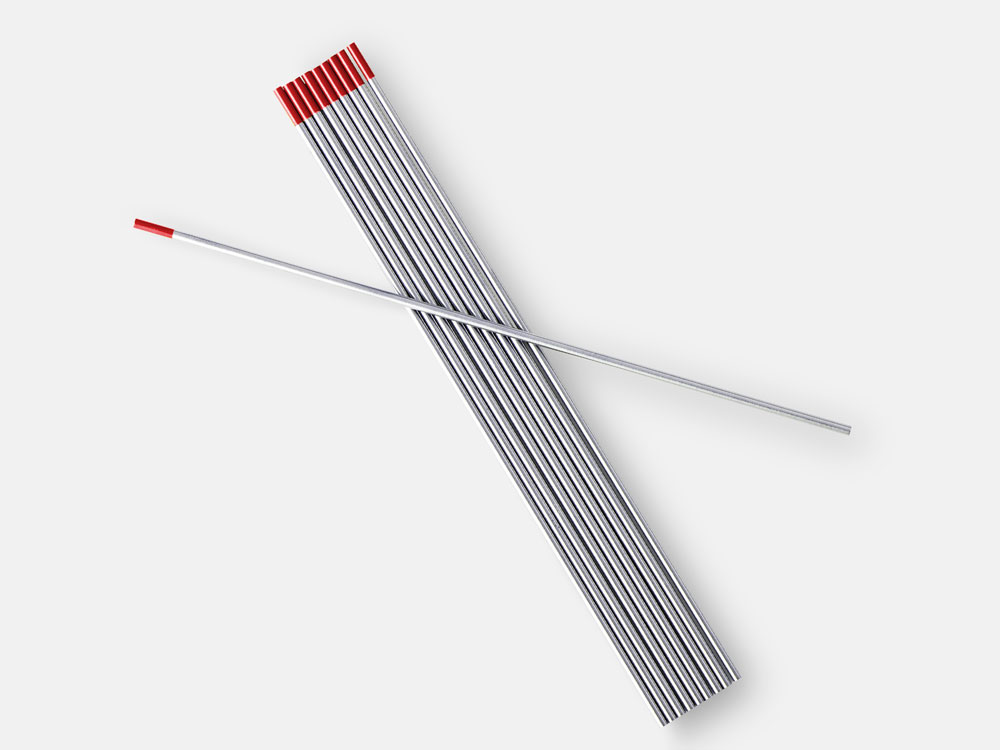

Thoriated Tungsten Electrode

Price 200.0 INR / Gram

Minimum Order Quantity : 1000 Kilograms

Material : TUNGSTEN

Color : GREY

Usage : WELDING

EBOND E6013

Price 1799 INR / Pack

Minimum Order Quantity : 200 Packs

Material : Mild Steel

Color : Silver

E Ni-1

Price 200.0 INR / Piece

Minimum Order Quantity : 100 Pieces

Material : NICKEL ALLOYS

Color : GREY

Usage : Welding

E Ni-Ci

Price 200.0 INR / Piece

Minimum Order Quantity : 100 Pieces

Material : NICKEL ALLOYS

Color : GREY

Usage : Welding

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry