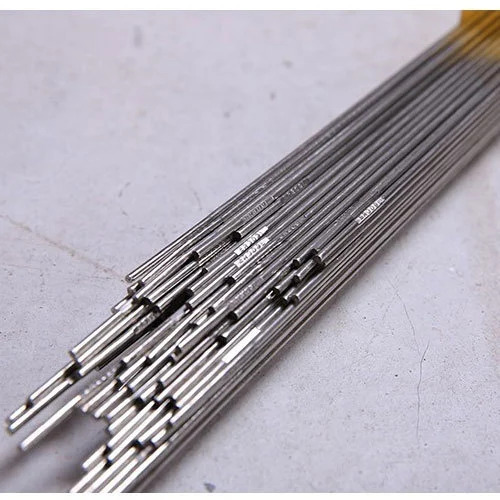

ER NiCrFe 2

Price 200.0 INR/ Roll

MOQ : 1 Kilograms

ER NiCrFe 2 Specification

- Application

- Welding purpose

- Diameter

- 1 Millimeter (mm)

- Type

- Welding Wire

- Condition

- New

- Material

- Nickel Alloy Wire

- Color

- silver

ER NiCrFe 2 Trade Information

- Minimum Order Quantity

- 1 Kilograms

- Delivery Time

- 3 Days

About ER NiCrFe 2

ER NiCrFe-2 (AWS A5.11 ENiCrFe-2) is a high-nickel alloy filler metal (electrode/wire) for welding nickel-chromium-iron alloys like Inconel 600/625, stainless steels, and dissimilar metals, offering excellent corrosion/oxidation resistance, strength from cryogenic to high temperatures (up to ~1500F/800C), used in chemical, power, and marine industries for tanks, piping, and overlays, with key elements being Nickel, Chromium, Iron, Molybdenum, and Niobium.

Key Characteristics:

- Composition: High Nickel (Ni), Chromium (Cr), Iron (Fe), with Molybdenum (Mo) and Niobium (Nb).

- Properties: Excellent high-temperature strength, oxidation resistance, corrosion resistance, good ductility, resists embrittlement and creep.

- Applications: Welding Inconel 600, 9% Nickel steels (cryogenic tanks), dissimilar joints (stainless to carbon steel), overlay cladding, chemical processing, power plants.

- Service Range: Cryogenic to high temperatures (up to 1500F/800C).

- Welding: Used with DCEP (Direct Current Electrode Positive) current, suitable for all positions (flat, vertical, overhead).

Common Uses:

- Welding Incoloy 825, Inconel 600/625.

- Joining various stainless steels, carbon steels, and nickel alloys.

- Repair and maintenance in harsh environments.

- Cryogenic storage tanks (for LNG/LPG).

In essence, it's a versatile, robust welding material for demanding, high-temperature, and corrosive environments, especially for joining different types of metals.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Welding Wire Category

ER NiCu7

Price 200.0 INR / Kilograms

Minimum Order Quantity : 15 Kilograms

Welding : FluxCored

Condition : New

Application : WELDING

Material : CHROME MOLY

ER 80SNi 2

Price 200.0 INR / Kilograms

Minimum Order Quantity : 15 Kilograms

Welding : MIG, TIG

Condition : New

Application : WELDING

Material : MILD STEEL

ER 308H

Price 200.0 INR / Kilograms

Minimum Order Quantity : 15 Kilograms

Welding : MIG, TIG

Condition : New

Application : WELDING

Material : STAINLESS STEEL

ER NiCrCoMo 1

Price 200.0 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Welding : MIG, TIG

Condition : New

Application : Welding

Material : NICKEL ALLOYS

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry