ER 5356 WELDING WIRE

Price 450.0 INR/ Kilogram

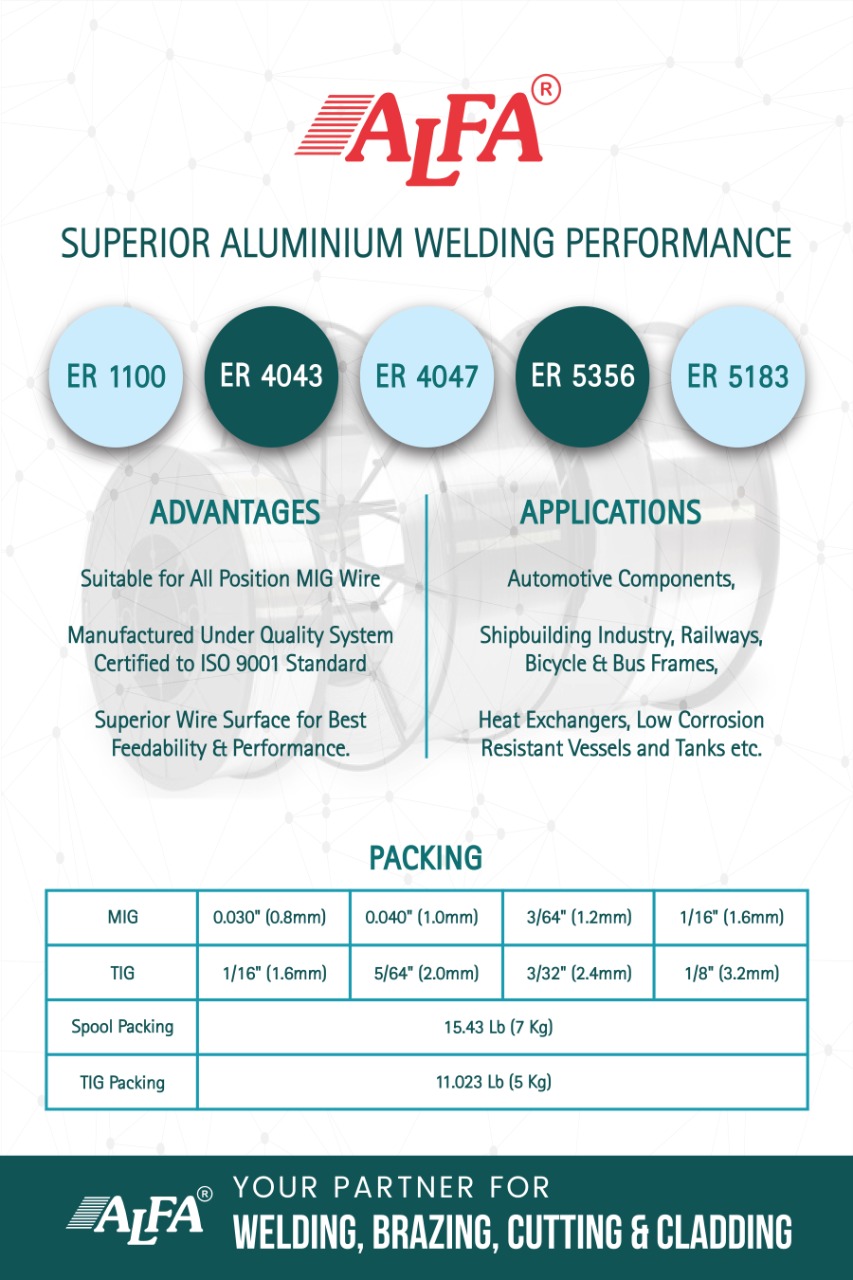

ER 5356 WELDING WIRE Specification

- Equipment Type

- Welding Consumable

- Diameter

- 0.8 mm, 1.0 mm, 1.2 mm (others available on request) Millimeter (mm)

- Current Range

- Depends on welding parameters Volt (V)

- Power Source

- Welding Machine

- Application

- Welding of Aluminium-Magnesium alloys

- Automation Grade

- Manual/Semi-Automatic

- Usage

- FOAM WORK

- Type

- Welding Wire

- Condition

- New

- Size

- 1.2 mm , 1.6 mm

- Material

- Aluminium Alloy (Approx. 5% Mg)

- Product Type

- ALUMINIUM WIRE

- Weight

- 15 GSM (gm/2)

- Color

- SILVER

- Dimensions

- Spool: Standard 1 kg, 5 kg, 7 kg, 15 kg or as required Millimeter (mm)

- Elongation

- 17% Minimum

- Melting Point

- Approx. 575°C

- AWS Specification

- AWS/SFA-5.10, ER5356

- Shielding Gas

- Argon or Argon Based Mixtures

- Surface Finish

- Bright

- Packaging Type

- Spools and Drums

- UTS (Ultimate Tensile Strength)

- Up to 275 MPa

ER 5356 WELDING WIRE Trade Information

- Minimum Order Quantity

- 25 Kilogram

- FOB Port

- JNPT

- Supply Ability

- 2000 Per Week

- Delivery Time

- 1 Days

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Packaging Details

- 5 KG IN TIG 7 KG IN MIG

- Main Export Market(s)

- Asia, Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Certifications

- AWS CE DNV

About ER 5356 WELDING WIRE

Experience weld perfection with our hot-selling ER 5356 Welding Wire, the elite choice among best-sellers for aluminium-magnesium alloy applications. Engineered to AWS/SFA-5.10 standards, this top-drawer consumable boasts unmatchable tensile strength of up to 275 MPa and a virtuoso elongation of 17% minimum, ensuring robust and durable welds. With a bright surface finish and available in versatile diameters-0.8 mm, 1.0 mm, 1.2 mm (others upon request)-it suits both manual and semi-automatic processes. Packaged conveniently in spools or drums, ER 5356 is the premium solution for MIG welding with argon shielding gas, enhancing efficiency for manufacturers, importers, suppliers, and traders alike.

Expanding Applications and Commercial Uses

ER 5356 Welding Wire's elite performance extends beyond traditional aluminum-magnesium alloy welding; it's widely applied in automotive parts, marine structures, and manufacturing of tanks and pressure vessels. Its unmatchable reliability makes it ideal in commercial fabrication, aerospace, and construction. Top-drawer versatility empowers repair shops, large industrial plants, and small businesses to achieve virtuoso results across different sectors, enhancing structural integrity and aesthetic appeal wherever high-quality aluminum welding is needed.

Order Processing, Sample Availability, and FOB Port Details

Order ER 5356 Welding Wire efficiently with a clear purchase order to initiate the process. Our sample policy allows customers to request samples for evaluation before placing bulk orders; samples are available upon proposal amount confirmation and order processing. We ship from reliable FOB ports to ensure prompt delivery worldwide. This streamlined experience lets importers, manufacturers, and traders confidently assure quality and performance prior to committing to full-scale procurement.

Expanding Applications and Commercial Uses

ER 5356 Welding Wire's elite performance extends beyond traditional aluminum-magnesium alloy welding; it's widely applied in automotive parts, marine structures, and manufacturing of tanks and pressure vessels. Its unmatchable reliability makes it ideal in commercial fabrication, aerospace, and construction. Top-drawer versatility empowers repair shops, large industrial plants, and small businesses to achieve virtuoso results across different sectors, enhancing structural integrity and aesthetic appeal wherever high-quality aluminum welding is needed.

Order Processing, Sample Availability, and FOB Port Details

Order ER 5356 Welding Wire efficiently with a clear purchase order to initiate the process. Our sample policy allows customers to request samples for evaluation before placing bulk orders; samples are available upon proposal amount confirmation and order processing. We ship from reliable FOB ports to ensure prompt delivery worldwide. This streamlined experience lets importers, manufacturers, and traders confidently assure quality and performance prior to committing to full-scale procurement.

FAQ's of ER 5356 WELDING WIRE:

Q: How is ER 5356 Welding Wire used for welding aluminium-magnesium alloys?

A: ER 5356 Welding Wire is specifically designed to join aluminium-magnesium alloys using MIG welding processes. It requires an argon or argon-based shielding gas and can be operated manually or semi-automatically, ensuring clean, strong, and corrosion-resistant welds.Q: What are the benefits of choosing ER 5356 over other welding wires?

A: ER 5356 offers unmatchable tensile strength, excellent elongation, and a bright surface finish, making it ideal for applications demanding durability and aesthetic quality. Its elite formula provides versatile compatibility and strong performance in both commercial and specialty sectors.Q: Where can ER 5356 Welding Wire be applied commercially?

A: This top-drawer wire finds usage in automotive parts, marine vessels, pressure tanks, construction, aerospace, and general fabrication, delivering virtuoso results in environments where robust and reliable aluminium welds are required.Q: What is the process to request a sample of ER 5356 Welding Wire?

A: To request a sample, submit a formal purchase order or proposal amount. Upon order processing, samples are dispatched for evaluation, enabling customers to assess quality prior to bulk purchases.Q: What diameters and packaging options are available for ER 5356?

A: ER 5356 is available in diameters of 0.8 mm, 1.0 mm, and 1.2 mm, with other options upon request. Packaging includes standard spools of 1 kg, 5 kg, 7 kg, 15 kg, or custom sizes, as well as drums for larger requirements.Q: When should ER 5356 be used for welding aluminum alloys?

A: Use ER 5356 when welding 5% magnesium aluminum alloys in projects that require high tensile strength, corrosion resistance, and professional-quality welds, especially in demanding commercial or industrial applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Welding Wire Category

ER 310 SS WIRE

Price 20.0 INR / Unit

Minimum Order Quantity : 15 Kilograms

Condition : New

Material : STAINLESS STEEL

Color : SILVER

Welding : FluxCored

ER 410

Price 200.0 INR / Kilograms

Minimum Order Quantity : 15 Kilograms

Condition : New

Material : STAINLESS STEEL

Color : SILVER

Welding : MIG, TIG

ER 317L

Price 200.0 INR / Kilograms

Minimum Order Quantity : 15 Kilograms

Condition : New

Material : STAINLESS STEEL

Color : SILVER

Welding : MIG, TIG

ER CuSi

Price 200.0 INR / Kilograms

Minimum Order Quantity : 15 Kilograms

Condition : New

Material : COPPER SILICON

Color : BRONZE

Welding : MIG, TIG

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry